29 May 2025

Savannah Resources Plc

(AIM: SAV) ('Savannah', or the 'Company')

Further robust zones of near surface higher-grade lithium mineralisation at Pinheiro and Reservatório

Savannah Resources plc, the developer of the Barroso Lithium Project (the 'Project') in Portugal, Europe's largest spodumene lithium deposit, is pleased to announce the third batch of assay results from Phase 2 of its Definitive Feasibility Study ('DFS') drilling programme at the Project. The 117-hole, c.13,000m programme is being undertaken for further JORC Resource definition, geotechnical and metallurgical purposes and today's results further highlight the potential for greater resources to be defined at the Project.

Highlights:

· The Phase 2 drill programme for the DFS is moving towards completion, primarily targeting the Pinheiro, Reservatório and Grandão deposits.

· To date 86 holes have been drilled for c. 10,393m in the planned 117 hole/c.13,000m programme.

· New Significant lithium assays have been received from a further 26 holes (3 at Pinheiro, 21 at Reservatório and 2 at Grandão), taking the total number of holes assayed to date to 68.

· At Pinheiro, we are continuing to intersect broad zones of higher-grade lithium mineralisation both near the surface and at depth on a routine basis. New intersections include:

o 43m @1.24% Li2O from 15m in hole 25PNRRC034, including 5m @1.93% Li2O

o 30m @1.5% Li2O from 46m in hole 25PNRRC035, including 6m @1.82% Li2O

o 19m @1.25% Li2O from 50m in hole 25PNRDD015, including 8m @1.73% Li2O and 47m @1.29% Li2O from 73m including 9.2m @1.81% Li2O making a total of 70m of near continuous mineralisation

· At Reservatório, results continue to give very encouraging indications of multiple zones of higher-grade mineralisation and confirm the potential expansion of the resource to the northeast. Better intersections include:

o 38m @1.67% Li2O from 41m in hole 25RESRC070, including 6m @2.17% Li2O

o 34.91m @1.24% Li2O from 99m in hole 25RESRC054 (includes 23.1m @ 1.28% Li20 from 99m previously reported from RC drilling)

o 31m @1.23% Li2O from 71m in hole 25RESRC084

o 30m @1.26% Li2O from 30m in hole 25RESRC066

o 28m @1.17% Li2O from 42m in hole 25RESRC080, and 9m @ 0.86% Li2O from 96m

o 26m @1.33% Li2O from 49m in hole 25RESRC068

o 26m @1.10% Li2O from 72m in hole 25RESRC062

o 21m @1.19% Li2O from 100m and 13m @ 0.79% Li2O from 124m in hole 25RESRC082

· Recent results from Grandão confirm that mineralisation continues along strike and down dip with results including:

o 7m @1.38% Li2O from 65m in hole 25GRARC144, including 4m @1.5% Li2O

o 6m @0.97% Li2O from 13m in hole 24GRARC147 and 4m @1.03% Li2O from 23m and 11m @0.97% Li2O from 30m

Savannah's Technical Director, Dale Ferguson said, "We have now completed 80% of the Phase 2 DFS drill programme and we are moving towards the completion of this critical phase of work. We are continuing to see further higher-grade zones of lithium mineralisation at Pinheiro combined with very good widths. This points towards the potential for an increase in the size of the Pinheiro resource and overall grade (last estimated at 2.0Mt at 1.0% Li2O, Inferred). The recent batch of drilling results from Reservatório is also very encouraging with results suggesting there is potential to extend the resource further to the northeast.

"Overall, the potential for greater resources at the Project is reiterated by each batch of assays we receive. With the end of the programme approaching, the focus is now turning to the update of the JORC Resource models for the Grandão, Reservatório, and Pinheiro orebodies and the definition of a new Exploration Target[1] for the project (previously estimated at 11-19Mt at 1.0-1.2% Li2O)."

Further Information

As previously announced, Savannah started Phase 2 of the DFS-related drilling programme at the Barroso Lithium Project in January 2025 (Figure 1). The programme consists of drilling for resource, metallurgical and geotechnical purposes using primarily Reverse Circulation ('RC') rigs with some supplementary diamond drilling (DD). To date, over 10,000m of drilling has been completed of the c.13,000m initially planned for Phase 2. The programme is ongoing, and further updates will be provided as more results are received.

Figure 1. Barroso Lithium Project summary map showing deposits and drill hole locations.

Pinheiro

The JORC Resource estimate for the Pinheiro deposit (all Inferred as at May 2024) is 2.0Mt at 1.0% Li2O.

Results from the Pinheiro drilling continue to be positive with regular intersection of robust higher-grade zones of lithium mineralisation. We are particularly encouraged by the results from hole 25PNRDD015, a planned geotechnical hole, which intersected the pegmatite at an unmapped location and followed a zone of over 70m of virtually continuous lithium mineralisation down dip. Drill hole 25PNRRC034 is the northern most planned hole and intersected high-grade mineralisation across the width of the pegmatite, which points towards the excellent potential for an expansion of the current resource.

Significant recent lithium mineralisation intersections at Pinheiro include:

o 19m @1.25% Li2O from 50m in hole 25PNRDD015, including 8m @1.73% Li2O, and 47m @1.29% Li2O from 73m, including 9.2m @1.81% Li2O.

o 43m @1.24% Li2O from 15m in hole 25PNRRC034, including 5m @1.93% Li2O

o 30m @1.5% Li2O from 46m in hole 25PNRRC035, including 6m @1.82% Li2O, 2m @1.88% Li2O, 2m @2.07% Li2O and 2m @1.81% Li2O

Figure 2. Location of Phase 2 diamond drilling at Pinheiro with significant intercepts to date.

Figure 3. Cross section 1 Eastern Pegmatite of Pinheiro deposit (Section A-A').

Reservatório

The JORC Resource estimate for the Reservatório deposit (Indicated & Inferred as of May 2024) is 4.2Mt at 0.9% Li2O.

The drilling at Reservatório continued to deliver excellent results with multiple intersects, showing geological consistency, including in the areas where some natural variations were found in the first results received for the east end of the pegmatite. The latest results include encouraging intersects at the northeastern portion of the resource, which continue to point towards the potential for an expansion of the resource in this direction.

Significant mineralised intersections at Reservatório include:

o 38m @1.67% Li2O from 41m in hole 25RESRC070, including 6m @2.17% Li2O

o 34.91m @1.24% Li2O from 99m in hole 25RESRC054, (includes 23.1m @ 1.28% Li20 from 99m previously reported from RC drilling)

o 31m @1.23% Li2O from 71m in hole 25RESRC084

o 30m @1.26% Li2O from 30m in hole 25RESRC066, including 3m @1.80% Li2O

o 28m @1.17% Li2O from 42m in hole 25RESRC080, including 6m @1.55% Li2O

o 27m @1.25% Li2O from 100m in hole 25RESRC050, including 10m @1.40% Li2O

o 26m @1.33% Li2O from 49m in hole 25RESRC068

o 26m @1.10% Li2O from 72m in hole 25RESRC062, including 4m @1.49% Li2O

o 18m @1.10% Li2O from 82m in hole 25RESRC083, including 5m @1.52% Li2O

o 16m @1.25% Li2O from 86m in hole 25RESRC061, including 3m @1.68% Li2O

o 17m @1.31% Li2O from 29m in hole 25RESRC069, and 14m @1.07% Li2O from 69m

o 13m @1.43% Li2O from 125m in hole 25RESRC071, including 4m @1.98% Li2O

o 15m @1.01% Li2O from 61m in hole 25RESRC079, 5m @0.76% Li2O from 82m, 6m @0.75% Li2O from 109m

o 5m @1.03% Li2O from 89m in hole 25RESRC082, and 21m @1.19% Li2O from 100m and 13m @ 0.79% Li2O from 124m

Drilling operations at Reservatório are still in progress, in the deeper portions dipping to the north.

Figure 5. Location of Phase 2 diamond drilling at Reservatório with significant intercepts from assays results.

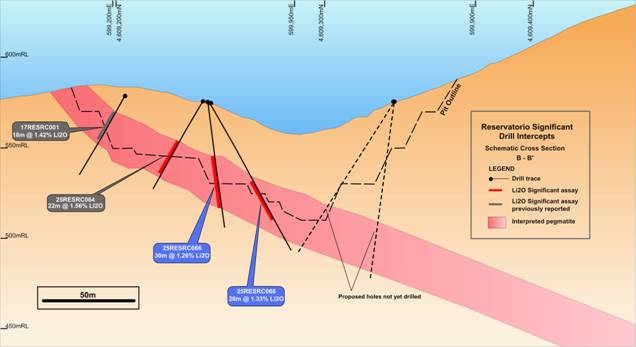

Figure 6. Cross section 2 of Reservatório deposit (Section A - A').

Figure 7. Cross section 2 of Reservatório deposit (Section B - B').

Grandão

The JORC Resource estimate for the Grandão deposit (Measured, Indicated & Inferred as of May 2024) is 17.7Mt at 1.04% Li2O.

The drilling at Grandão has continued to focus primarily on the southern extremities of the pegmatite and where it occurs nearer to the surface and will be part of the preliminary mining stages. The drilling has shown that the southern edge is thinner than the central part of the pegmatite with widths varying between 3m to 20m.

Significant mineralised intersections at Grandão include:

o 7m @1.38% Li2O from 65m in hole 25GRARC144, including 4m @1.5% Li2O

o 6m @0.97% Li2O from 13m in hole 24GRARC147 and 4m @1.03% Li2O from 23m and 11m @ 0.97% Li2O from 30m

Figure 9. Location of Phase 2 drilling at Grandão with significant intercepts from assays results.

Next steps

The initial stage of the Phase 2 drilling is nearing completion and the results from this will feed into upgrading the confidence level of the existing resource estimations for each deposit. On top of this, it is planned to drill the Aldeia A deposit with the aim to infill the drilling to gain a 40m x 40m coverage to upgrade the existing Resource (3.5Mt at 1.3% Li2O) that was previously outlined in 2019.

In conjunction with resource drilling, preparation of the specific requirements of core samples for metallurgical testing has commenced. Once results have been received the specific sample requirements requested by Savannah's metallurgical consultants will be sorted and sent for testing.

The drilling of diamond drill holes for geotechnical testing is complete at Pinheiro and is currently being carried out at Grandão and then onto Reservatório. The results from this programme will be used to aid in the design of the various mining pits to ensure maximum extraction of ore under safe and sustainable conditions.

Competent Person and Regulatory Information

The information in this announcement that relates to exploration results is based upon information compiled by Mr Dale Ferguson, Technical Director of Savannah Resources Limited. Mr Ferguson is a Member of the Australasian Institute of Mining and Metallurgy (AusIMM) and has sufficient experience which is relevant to the style of mineralisation and type of deposit under consideration and to the activity which he is undertaking to qualify as a Competent Person as defined in the December 2012 edition of the "Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves" (JORC Code) and as a qualified person under the AIM Rules. Mr Ferguson consents to the inclusion in the report of the matters based upon the information in the form and context in which it appears.

Regulatory Information

This Announcement contains inside information for the purposes of the UK version of the market abuse regulation (EU No. 596/2014) as it forms part of United Kingdom domestic law by virtue of the European Union (Withdrawal) Act 2018 ("UK MAR").

Savannah - Enabling Europe's energy transition.

**ENDS**

Follow @SavannahRes on X (Formerly known as Twitter)

Follow Savannah Resources on LinkedIn

Follow Savannah Resources on LinkedIn

For further information please visit www.savannahresources.com or contact:

|

Savannah Resources PLC Emanuel Proença, CEO |

Tel: 44 20 7117 2489

|

|

SP Angel Corporate Finance LLP (Nominated Advisor & Broker) David Hignell/ Charlie Bouverat (Corporate Finance) Grant Barker/Abigail Wayne (Sales & Broking)

|

Tel: 44 20 3470 0470

|

|

Canaccord Genuity Limited (Joint Broker) James Asensio / Charlie Hammond (Corporate Broking) Ben Knott (Sales) |

Tel: 44 20 7523 8000

|

|

Camarco (UK Financial PR) Gordon Poole/ Emily Hall / Nuthara Bandara |

Tel: 44 20 3757 4980 |

|

Portugal Media Relations Savannah Resources: Antonio Neves Costa, Communications Manager |

Tel: 351 962 678 912 |

About Savannah

Savannah Resources is a mineral resource development company and the sole owner of the Barroso Lithium Project (the 'Project') in northern Portugal. The Project is the largest battery-grade spodumene lithium resource outlined to date in Europe and was classified as a 'Strategic Project' by the European Commission under the Critical Raw Materials Act in March 2025.

Through the Project, Savannah will help Portugal to play an important role in providing a long-term, locally sourced, lithium raw material supply for Europe's lithium battery value chain. Once in operation, the Project will produce enough lithium (contained in c.190,000tpa of spodumene concentrate) for approximately half a million vehicle battery packs per year and hence make a significant contribution towards the European Commission's Critical Raw Material Act goal of a minimum 10% of European endogenous lithium production from 2030. Savannah is focused on the responsible development and operation of the Barroso Lithium Project so that its impact on the environment is minimised and the socio-economic benefits that it can bring to all its stakeholders are maximised.

The Company is listed and regulated on the AIM Market of the London Stock Exchange and trades under the ticker "SAV".APPENDIX 1: Drill hole locations of Completed Phase 2 RC and Diamond Resource Holes (* with assays)

|

Hole ID |

Prospect |

Hole Type |

Tot Depth (m) |

|

Easting |

Northing |

RL |

Dip |

Azimuth |

|

25GRADD048 |

Grandão |

DD |

128.25 |

|

601650 |

4607783 |

567 |

-50 |

190 |

|

25GRADD049 |

Grandão |

DD |

120.7 |

|

601516 |

4607909 |

507 |

-50 |

230 |

|

25GRARC134* |

Grandão |

RC |

30 |

|

601928 |

4607805 |

578 |

-90 |

0 |

|

25GRARC135* |

Grandão |

RC |

50 |

|

601889 |

4607672 |

587 |

-90 |

0 |

|

25GRARC136* |

Grandão |

RC |

40 |

|

601884 |

4607651 |

595 |

-90 |

0 |

|

25GRARC137* |

Grandão |

RC |

80 |

|

601772 |

4607635 |

606 |

-90 |

0 |

|

25GRARC138* |

Grandão |

RC |

80 |

|

601776 |

4607634 |

606 |

-60 |

90 |

|

25GRARC139* |

Grandão |

RC |

84 |

|

601803 |

4607696 |

577 |

-90 |

0 |

|

25GRARC140* |

Grandão |

RCDD |

28.6 |

|

601817 |

4607719 |

562 |

-90 |

0 |

|

25GRARC141* |

Grandão |

RC |

90 |

|

601787 |

4607763 |

551 |

-72 |

90 |

|

25GRARC142 |

Grandão |

RCDD |

49 |

|

601734 |

4607675 |

596 |

-60 |

90 |

|

25GRARC143 |

Grandão |

RCDD |

50 |

|

601732 |

4607675 |

597 |

-90 |

0 |

|

25GRARC144* |

Grandão |

RC |

170 |

|

601730 |

4607716 |

582 |

-70 |

90 |

|

25GRARC145 |

Grandão |

RC |

142 |

|

601729 |

4607716 |

582 |

-90 |

0 |

|

25GRARC146 |

Grandão |

RCDD |

122.25 |

|

601634 |

4608025 |

504 |

-60 |

120 |

|

25GRARC147* |

Grandão |

RC |

141 |

|

601742 |

4608055 |

539 |

-65 |

45 |

|

25GRARC148 |

Grandão |

RC |

128.25 |

|

601650 |

4607783 |

568 |

-50 |

190 |

|

25GRARC149 |

Grandão |

RC |

120.70 |

|

601517 |

4607910 |

507 |

-50 |

230 |

|

25PNRDD009* |

Pinheiro |

DD |

84.85 |

|

601594 |

4606830 |

580 |

-60 |

270 |

|

25PNRDD010 |

Pinheiro |

DD |

110.35 |

|

601590 |

4606831 |

584 |

-57 |

215 |

|

25PNRDD011* |

Pinheiro |

DD |

120.75 |

|

601583 |

4606909 |

575 |

-50 |

263 |

|

25PNRDD012 |

Pinheiro |

DD |

101.2 |

|

601579 |

4606910 |

575 |

-50 |

63 |

|

25PNRDD013* |

Pinheiro |

DD |

124.9 |

|

601399 |

4606803 |

538 |

-60 |

90 |

|

25PNRDD014 |

Pinheiro |

DD |

111.8 |

|

601414 |

4606856 |

561 |

-50 |

185 |

|

25PNRDD015* |

Pinheiro |

DD |

126.8 |

|

601598 |

4607011 |

583 |

-50 |

310 |

|

25PNRDD016 |

Pinheiro |

DD |

108.3 |

|

601399 |

4606802 |

538 |

-50 |

110 |

|

25PNRDD017 |

Pinheiro |

DD |

100.1 |

|

601599 |

4607011 |

583 |

-62 |

310 |

|

25PNRDD018 |

Pinheiro |

DD |

179.55 |

|

601637 |

4606994 |

572 |

-55 |

230 |

|

25PNRRC026* |

Pinheiro |

RCDD |

120 |

|

601607 |

4606920 |

573 |

-70 |

270 |

|

25PNRRC027* |

Pinheiro |

RC |

100 |

|

601578 |

4606879 |

581 |

-90 |

0 |

|

25PNRRC028* |

Pinheiro |

RCDD |

94.3 |

|

601577 |

4606879 |

581 |

-80 |

270 |

|

25PNRRC029* |

Pinheiro |

RC |

70 |

|

601575 |

4606878 |

581 |

-60 |

270 |

|

25PNRRC030* |

Pinheiro |

RC |

70 |

|

601430 |

4606800 |

554 |

-60 |

90 |

|

25PNRRC031* |

Pinheiro |

RCDD |

128.55 |

|

601599 |

4607010 |

583 |

-60 |

245 |

|

25PNRRC032* |

Pinheiro |

RC |

100 |

|

601639 |

4607036 |

584 |

-60 |

270 |

|

25PNRRC033 |

Pinheiro |

RCDD |

131.5 |

|

601636 |

4606995 |

573 |

-60 |

270 |

|

25PNRRC034* |

Pinheiro |

RC |

85 |

|

601664 |

4607061 |

591 |

-60 |

270 |

|

25PNRRC035* |

Pinheiro |

RC |

110 |

|

601589 |

4606977 |

572 |

-60 |

270 |

|

25RESDD015 |

Reservatório |

DD |

150,80 |

|

599507 |

4609100 |

615 |

-50 |

222 |

|

25RESDD016 |

Reservatório |

DD |

90,80 |

|

599869 |

4609271 |

577 |

-50 |

350 |

|

25RESRC046* |

Reservatório |

RCDD |

184.8 |

|

599583 |

4609279 |

639 |

-80 |

150 |

|

25RESRC047* |

Reservatório |

RCDD |

178.7 |

|

599585 |

4609275 |

639 |

-65 |

150 |

|

25RESRC048* |

Reservatório |

RCDD |

186.5 |

|

599498 |

4609187 |

641 |

-90 |

0 |

|

25RESRC049* |

Reservatório |

RCDD |

174 |

|

599500 |

4609184 |

641 |

-70 |

150 |

|

25RESRC050* |

Reservatório |

RCDD |

140.1 |

|

599520 |

4609147 |

631 |

-63 |

150 |

|

25RESRC051* |

Reservatório |

RCDD |

160.4 |

|

599618 |

4609287 |

620 |

-80 |

150 |

|

25RESRC052* |

Reservatório |

RCDD |

158.8 |

|

599620 |

4609285 |

619 |

-70 |

150 |

|

25RESRC053* |

Reservatório |

RC |

111 |

|

599695 |

4609242 |

613 |

-90 |

0 |

|

25RESRC054* |

Reservatório |

RCDD |

150.4 |

|

599656 |

4609309 |

604 |

-90 |

0 |

|

25RESRC055* |

Reservatório |

RCDD |

105 |

|

599657 |

4609306 |

604 |

-70 |

150 |

|

25RESRC056* |

Reservatório |

RCDD |

88 |

|

599913 |

4609253 |

577 |

-80 |

0 |

|

25RESRC057* |

Reservatório |

RC |

88 |

|

599915 |

4609247 |

577 |

-60 |

140 |

|

25RESRC058* |

Reservatório |

RCDD |

96 |

|

599710 |

4609302 |

593 |

-80 |

150 |

|

25RESRC059* |

Reservatório |

RC |

100 |

|

599950 |

4609211 |

586 |

-60 |

150 |

|

25RESRC060* |

Reservatório |

RC |

147 |

|

599712 |

4609299 |

593 |

-60 |

150 |

|

25RESRC061* |

Reservatório |

RC |

120 |

|

599783 |

4609267 |

588 |

-70 |

310 |

|

25RESRC062* |

Reservatório |

RC |

120 |

|

599784 |

4609266 |

588 |

-90 |

0 |

|

25RESRC063* |

Reservatório |

RC |

67 |

|

599934 |

4609230 |

581 |

-60 |

150 |

|

25RESRC064* |

Reservatório |

RC |

55 |

|

599970 |

4609238 |

575 |

-60 |

150 |

|

25RESRC065* |

Reservatório |

RC |

140 |

|

599503 |

4609102 |

617 |

-60 |

150 |

|

25RESRC066* |

Reservatório |

RC |

70 |

|

599970 |

4609241 |

575 |

-80 |

0 |

|

25RESRC067* |

Reservatório |

RCDD |

160.8 |

|

599481 |

4609136 |

628 |

-65 |

150 |

|

25RESRC068* |

Reservatório |

RC |

94 |

|

599968 |

4609241 |

575 |

-60 |

340 |

|

25RESRC069* |

Reservatório |

RC |

91 |

|

599901 |

4609215 |

594 |

-60 |

150 |

|

25RESRC070* |

Reservatório |

RC |

100 |

|

599888 |

4609236 |

589 |

-60 |

150 |

|

25RESRC071* |

Reservatório |

RCDD |

143 |

|

599480 |

4609138 |

628 |

-75 |

150 |

|

25RESRC072* |

Reservatório |

RC |

85 |

|

599889 |

4609238 |

589 |

-90 |

0 |

|

25RESRC073* |

Reservatório |

RCDD |

177.25 |

|

599479 |

4609139 |

628 |

-85 |

150 |

|

25RESRC074* |

Reservatório |

RC |

90 |

|

599586 |

4609050 |

607 |

-60 |

150 |

|

25RESRC075* |

Reservatório |

RCDD |

85 |

|

599863 |

4609275 |

579 |

-70 |

150 |

|

25RESRC076* |

Reservatório |

RC |

100 |

|

599568 |

4609080 |

614 |

-60 |

150 |

|

25RESRC077* |

Reservatório |

RC |

105 |

|

599566 |

4609082 |

614 |

-80 |

150 |

|

25RESRC078* |

Reservatório |

RCDD |

91 |

|

599863 |

4609276 |

579 |

-90 |

0 |

|

25RESRC079* |

Reservatório |

RC |

121 |

|

599733 |

4609259 |

603 |

-60 |

150 |

|

25RESRC080* |

Reservatório |

RC |

122 |

|

599800 |

4609219 |

606 |

-60 |

150 |

|

25RESRC081* |

Reservatório |

RC |

133 |

|

599799 |

4609221 |

606 |

-90 |

0 |

|

25RESRC082* |

Reservatório |

RC |

147 |

|

599801 |

4609224 |

606 |

-70 |

330 |

|

25RESRC083* |

Reservatório |

RC |

107 |

|

599852 |

4609221 |

600 |

-60 |

150 |

|

25RESRC084* |

Reservatório |

RC |

111 |

|

599852 |

4609222 |

600 |

-90 |

0 |

|

25RESRC085 |

Reservatório |

RC |

160 |

599710 |

4609308 |

597 |

-80 |

330 |

|

|

25RESRC086 |

Reservatório |

RC |

109.80 |

599710 |

4609303 |

594 |

-80 |

150 |

|

|

25RESRC087 |

Reservatório |

RC |

109 |

599826 |

4609268 |

584 |

-60 |

150 |

|

|

25RESRC088 |

Reservatório |

RC |

116 |

599827 |

4609270 |

585 |

-80 |

150 |

|

|

25RESRC089 |

Reservatório |

RC |

120 |

599827 |

4609271 |

585 |

-75 |

330 |

|

|

25RESRC090 |

Reservatório |

RC |

153 |

599827 |

4609271 |

585 |

-55 |

330 |

|

|

25RESRC091 |

Reservatório |

RC |

108 |

599862 |

4609278 |

576 |

-70 |

330 |

|

APPENDIX 2 - Summary of Significant Intercepts from the diamond drilling using a 0.5% Li2O Cutoff.

|

Hole ID |

Prospect |

From |

To |

Width |

Li20 |

|

25GRARC144 |

Grandão |

65 |

72 |

7 |

1.38 |

|

and |

Grandão |

104 |

114 |

10 |

0.82 |

|

and |

Grandão |

126 |

139 |

13 |

0.92 |

|

25GRARC145 |

Grandão |

50 |

62 |

12 |

0.79 |

|

and |

Grandão |

88 |

90 |

2 |

0.95 |

|

and |

Grandão |

103 |

107 |

4 |

1.24 |

|

and |

Grandão |

111 |

134 |

23 |

1.55 |

|

25GRARC146 |

Grandão |

60 |

75 |

15 |

0.98 |

|

25GRARC147 |

Grandão |

13 |

19 |

6 |

0.97 |

|

and |

Grandão |

23 |

27 |

4 |

1.03 |

|

and |

Grandão |

30 |

41 |

11 |

0.97 |

|

and |

Grandão |

68 |

72 |

4 |

0.51 |

|

and |

Grandão |

77 |

80 |

3 |

0.5 |

|

and |

Grandão |

115 |

118 |

3 |

0.61 |

|

25PNRDD015 |

Pinheiro |

14 |

29 |

15 |

0.7 |

|

and |

Pinheiro |

32 |

43 |

11 |

0.81 |

|

and |

Pinheiro |

50 |

69 |

19 |

1.25 |

|

and |

Pinheiro |

73 |

120 |

47 |

1.29 |

|

25PNRDD016 |

Pinheiro |

64.6 |

68.55 |

3.95 |

1.34 |

|

and |

Pinheiro |

71.25 |

76 |

4.75 |

1.07 |

|

25PNRRC034 |

Pinheiro |

15 |

58 |

43 |

1.24 |

|

and |

Pinheiro |

70 |

78 |

8 |

0.66 |

|

25PNRRC035 |

Pinheiro |

46 |

76 |

30 |

1.5 |

|

and |

Pinheiro |

81 |

84 |

3 |

0.71 |

|

25RESRC052** |

Reservatório |

124 |

139 |

15 |

0.77 |

|

and |

Reservatório |

144 |

149 |

5 |

1.09 |

|

25RESRC061 |

Reservatório |

86 |

102 |

16 |

1.25 |

|

25RESRC062 |

Reservatório |

72 |

98 |

26 |

1.1 |

|

25RESRC063 |

Reservatório |

35 |

38 |

3 |

1.04 |

|

and |

Reservatório |

42 |

44 |

2 |

0.86 |

|

25RESRC066 |

Reservatório |

30 |

60 |

30 |

1.26 |

|

25RESRC067 |

Reservatório |

127 |

131 |

4 |

1.38 |

|

25RESRC068 |

Reservatório |

49 |

75 |

26 |

1.33 |

|

25RESRC069 |

Reservatório |

16 |

19 |

3 |

0.88 |

|

and |

Reservatório |

29 |

46 |

17 |

1.31 |

|

and |

Reservatório |

69 |

83 |

14 |

1.07 |

|

25RESRC070 |

Reservatório |

41 |

79 |

38 |

1.67 |

|

25RESRC071 |

Reservatório |

30 |

33 |

3 |

0.9 |

|

and |

Reservatório |

125 |

138 |

13 |

1.43 |

|

and |

Reservatório |

141 |

143 |

2 |

0.76 |

|

25RESRC072 |

Reservatório |

64 |

67 |

3 |

0.9 |

|

and |

Reservatório |

73 |

78 |

5 |

0.93 |

|

25RESRC073 |

Reservatório |

30 |

33 |

3 |

1.02 |

|

and |

Reservatório |

133 |

140 |

7 |

1.47 |

|

25RESRC074 |

Reservatório |

65 |

73 |

8 |

0.89 |

|

25RESRC075 |

Reservatório |

66 |

70 |

4 |

1.52 |

|

25RESRC076 |

Reservatório |

63 |

68 |

5 |

0.8 |

|

and |

Reservatório |

74 |

80 |

6 |

1.03 |

|

and |

Reservatório |

83 |

91 |

8 |

1.04 |

|

25RESRC077 |

Reservatório |

62 |

68 |

6 |

0.83 |

|

and |

Reservatório |

72 |

75 |

3 |

0.81 |

|

and |

Reservatório |

78 |

80 |

2 |

0.82 |

|

and |

Reservatório |

85 |

91 |

6 |

0.94 |

|

25RESRC078* |

Reservatório |

Waiting for results from diamond tail |

|||

|

25RESRC079 |

Reservatório |

61 |

76 |

15 |

1.01 |

|

and |

Reservatório |

82 |

87 |

5 |

0.76 |

|

and |

Reservatório |

109 |

115 |

6 |

0.75 |

|

25RESRC080 |

Reservatório |

42 |

70 |

28 |

1.17 |

|

and |

Reservatório |

96 |

105 |

9 |

0.86 |

|

25RESRC081 |

Reservatório |

48 |

68 |

20 |

0.84 |

|

and |

Reservatório |

92 |

105 |

13 |

0.9 |

|

and |

Reservatório |

121 |

124 |

3 |

1.18 |

|

25RESRC082 |

Reservatório |

53 |

58 |

5 |

1.02 |

|

and |

Reservatório |

89 |

94 |

5 |

1.03 |

|

and |

Reservatório |

100 |

121 |

21 |

1.19 |

|

and |

Reservatório |

124 |

137 |

13 |

0.79 |

|

25RESRC083 |

Reservatório |

23 |

26 |

3 |

0.97 |

|

and |

Reservatório |

82 |

100 |

18 |

1.1 |

|

25RESRC084 |

Reservatório |

71 |

102 |

31 |

1.23 |

*Significant results from RC hole, diamond tail to follow

** From completed diamond tail

APPENDIX 3 - JORC 2012 Table 1 - DFS Infill Drilling

JORC Table 1 Section 1 Sampling Techniques and Data

|

Criteria |

JORC Code Explanation |

Commentary |

|

Sampling techniques |

· Nature and quality of sampling (e.g. cut channels, random chips, or specific specialised industry standard measurement tools appropriate to the minerals under investigation, such as down hole gamma sondes, or handheld XRF instruments, etc). These examples should not be taken as limiting the broad meaning of sampling. · Include reference to measures taken to ensure sample representivity and the appropriate calibration of any measurement tools or systems used. · Aspects of the determination of mineralisation that are Material to the Public Report. In cases where 'industry standard' work has been done this would be relatively simple (e.g. 'reverse circulation drilling was used to obtain 1 m samples from which 3 kg was pulverised to produce a 30 g charge for fire assay'). In other cases more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralisation types (e.g. submarine nodules) may warrant disclosure of detailed information. |

· The majority of previous holes were reverse circulation, sampled at 1m intervals. RC samples were collected in large plastic bags attached to the cyclone. On completion of the 1m run the large sample was passed through a 3-stage riffle splitter to collect a 2.5-4kg sub sample, to be used for assay. · Diamond holes were completed for metallurgical sampling, geotechnical analysis and resource estimation. Core was PQ/HQ size, sampled at 1m intervals in the pegmatite, with boundaries sampled to geological boundaries. Half core samples were collected for analysis. · Drilling was carried out to infill previous drilling to achieve a nominal 40m by 40m spacing with selected infill to 40m by 20m spacings, or as twins of previous RC drilling to get known samples for metallurgical testing. Geotechnical drilling was designed purely to intersect planned pit walls and pegmatite intersections were incidental, but followed all standard logging and sampling in line with all the drilling. · Collar surveys are carried using differential DGPS with an accuracy to within 0.2m. · A down hole survey for each hole was completed using gyro equipment. · The lithium mineralisation is predominantly in the form of Spodumene-bearing pegmatites, the pegmatites are unzoned and vary in thickness from 5m-109m.

|

|

Drilling techniques |

· Drill type (e.g. core, reverse circulation, open-hole hammer, rotary air blast, auger, Bangka, sonic, etc) and details (e.g. core diameter, triple or standard tube, depth of diamond tails, face-sampling bit or other type, whether core is oriented and if so, by what method, etc). |

• RC drilling used a 120mm diameter face sampling hammer. · Core drilling was carried out using PQ/HQ single tube core barrels.

|

|

Drill sample recovery |

· Method of recording and assessing core and chip sample recoveries and results assessed. · Measures taken to maximise sample recovery and ensure representative nature of the samples. · Whether a relationship exists between sample recovery and grade and whether sample bias may have occurred due to preferential loss/gain of fine/coarse material. |

· RC drilling sample weights were monitored to ensure samples were maximised. Samples were carefully loaded into a splitter and split in the same manner ensuring that the sample split to be sent to the assay laboratories were in the range of 4-6kg. · Core recovery was measured and was found to be generally excellent. · No obvious relationships between sample recovery and grade. |

|

Logging |

· Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation, mining studies and metallurgical studies. · Whether logging is qualitative or quantitative in nature. Core (or costean, channel, etc) photography. · The total length and percentage of the relevant intersections logged. |

· RC holes were logged in the field at the time of sampling. Core was logged in detail for a variety of physical characteristics in a logging yard away from the drilling · Each 1m sample interval was carefully homogenised and assessed for lithology, colour, grainsize, structure and mineralisation. Core was sampled to geological boundaries and at 1m intervals therein. · A representative chip sample produced from RC drilling was washed and taken for each 1m sample and stored in a chip tray which was photographed. · Percussion holes were logged for every metre drilled with the spoil collected for each metre by shovel and placed in a sample bag, a representative sub sample was taken and logged for lithology, colour, grainsize and mineralisation. · Core was photographed. |

|

Sub-sampling techniques and sample preparation |

· If core, whether cut or sawn and whether quarter, half or all core taken. · If non-core, whether riffled, tube sampled, rotary split, etc and whether sampled wet or dry. · For all sample types, the nature, quality and appropriateness of the sample preparation technique. · Quality control procedures adopted for all sub-sampling stages to maximise representivity of samples. · Measures taken to ensure that the sampling is representative of the in-situ material collected, including for instance results for field duplicate/second-half sampling. · Whether sample sizes are appropriate to the grain size of the material being sampled. |

· 1m RC samples were split by the riffle splitter at the drill rig and sampled dry. · Core was cut in half using a diamond saw with 1m half core samples submitted for analysis or for metallurgical samples one of the halves was cut again for a quarter core and sent for analysis. · The sampling was conducted using industry standard techniques and were considered appropriate. · Field duplicates were used to test repeatability of the sub-sampling and were found to be satisfactory. · Every effort was made to ensure that the samples were representative and not biased in any way.

|

|

Quality of assay data and laboratory tests |

· The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total. · For geophysical tools, spectrometers, handheld XRF instruments, etc, the parameters used in determining the analysis including instrument make and model, reading times, calibrations factors applied and their derivation, etc. · Nature of quality control procedures adopted (e.g. standards, blanks, duplicates, external laboratory checks) and whether acceptable levels of accuracy (i.e. lack of bias) and precision have been established. |

· Samples were received, sorted, labelled, and dried. · Samples were crushed to 70% less than 2mm, riffle split off 250g, pulverise split to better than 85% passing 75 microns and 5g was split of for assaying. · The samples were analysed using ALS Laboratories ME-MS89L Super Trace method which combines a sodium peroxide fusion with ICP-MS instrumentation utilising collision/reaction cell technologies to provide the lowest detection limits available. · A prepared sample (0.2g) is added to sodium peroxide flux, mixed well and then fused in at 670°C. The resulting melt is cooled and then dissolved in 30% hydrochloric acid. This solution is then analysed by ICP-MS and the results are corrected for spectral inter-element interferences. · The final solution is then analysed by ICP-MS, with results corrected for spectral inter-element interferences. · Standards/blanks and duplicates were inserted on a 1:20 ratio for both to samples taken. · Duplicate sample regime is used to monitor sampling methodology and homogeneity. · Routine QA/QC controls for the method ME-MS89L include blanks, certified reference standards of Lithium and duplicate samples. Samples are assayed within runs or batches up to 150 samples. At the fusion stage that quality control samples are included together with the samples, so all samples follow the same procedure until the end. Fused and diluted samples are prepared for ICP-MS analysis. ICP instrument is calibrated through appropriate certified standards solutions and interference corrections to achieve strict calibration fitting parameters. Each 40-sample run is assayed with two blanks, two certified standards and one duplicate sample and results are evaluated accordingly. · A QA/QC review of all information indicated that all assays were satisfactory. |

|

Verification of sampling and assaying |

· The verification of significant intersections by either independent or alternative company personnel. · The use of twinned holes. · Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols. · Discuss any adjustment to assay data. |

· All information was internally audited by company personnel. · During this programme no holes were twinned. · Savannah's experienced project geologists supervised all processes. · All field data is entered into a custom log sheet and then into excel spreadsheets (supported by look-up tables) at site and subsequently validated as it is imported into the centralised Access database. · Hard copies of logs, survey and sampling data are stored in the local office and electronic data is stored on the company's cloud drive. · Results were reported as Li (ppm) and were converted to a percentage by dividing by 10,000 and then to Li2O% by multiplying by 2.153. |

|

Location of data points |

· Accuracy and quality of surveys used to locate drill holes (collar and down-hole surveys), trenches, mine workings and other locations used in Mineral Resource estimation. · Specification of the grid system used. · Quality and adequacy of topographic control. |

· The coordinate of each drill hole was taken at the time of collecting using a handheld GPS with an accuracy of 5m. All collars were subsequently surveyed using DGPS with an accuracy of 0.2m. · The grid system used is WSG84 Zone29N. · An accurate, aerial topographic survey was obtained with accuracy of /- 0.5m. |

|

Data spacing and distribution |

· Data spacing for reporting of Exploration Results. · Whether the data spacing and distribution is sufficient to establish the degree of geological and grade continuity appropriate for the Mineral Resource and Ore Reserve estimation procedure(s) and classifications applied. · Whether sample compositing has been applied. |

· Drilling was carried out on an infill basis to attain on a nominal 40m by 40m and based on geological targets with selected infill to 40m by 20m. · Drill data is considered of sufficient spacing to define Measured and Indicated Mineral Resource in accordance with requirements for a DFS · Compositing to 1m will be applied prior to resource estimation. |

|

Orientation of data in relation to geological structure |

· Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known, considering the deposit type. · If the relationship between the drilling orientation and the orientation of key mineralised structures is considered to have introduced a sampling bias, this should be assessed and reported if material. |

· Drilling was generally carried out using angled holes, as close to perpendicular to strike as possible. All Geotech holes were drilled in various orientations to intersect planned pit walls. According to the expert (GGC - Consultants) requirements. |

|

Sample security |

· The measures taken to ensure sample security. |

· Samples were delivered to a courier and chain of custody is managed by Savannah. |

|

Audits or reviews |

· The results of any audits or reviews of sampling techniques and data. |

· Internal company auditing based on previous programmes is carried out and an external review will be carried out by the resource consultant to assure that all data collection and QA/QC procedures were conducted to industry standards. |

JORC Table 1 Section 2 Reporting of Exploration Results

|

Criteria |

JORC Code explanation |

Commentary |

|

Mineral tenement and land tenure status |

· Type, reference name/number, location and ownership including agreements or material issues with third parties such as joint ventures, partnerships, overriding royalties, native title interests, historical sites, wilderness or national park and environmental settings. · The security of the tenure held at the time of reporting along with any known impediments to obtaining a license to operate in the area. |

· All work was completed inside the Mina do Barroso project C-100. · Savannah has received written confirmation from the DGEG that under article 24 of Decree-Law no. 88/90 of March 16 being relevant justification based on the resources allocated exploited and intended, Savannah has been approved an expansion up to 250m of C100 mining concession in specific areas where a resource has been defined and the requirement for the expansion can be justified. · The entire Phase 2 includes a total of 117 drill holes. The surface access was granted by an administrative easement right defined in the C-100 mining contract, 95 of the drill holes were included in a first easement process, and the remaining 22 were subject to second easement that is still in progress. |

|

Exploration done by other parties |

· Acknowledgment and appraisal of exploration by other parties. |

· Limited exploration work has been carried out by previous operators. · No historic information has been included in the Mineral Resource estimates. |

|

Geology |

· Deposit type, geological setting and style of mineralisation. |

· The lithium mineralisation is predominantly in the form of Spodumene-bearing pegmatites which are hosted in meta-pelitic and mica schists, and occasionally carbonate schists of upper Ordovician to lower Devonian age. The pegmatites vary in thickness from 5m-109m. The pegmatites occur within the license area as discrete bodies and currently four pegmatite bodies have a resource defined on them. The pegmatites vary in orientation from large shallow dipping bodies, such as the north - south striking Grandão and the east - west trending Reservatório to steeply dipping dyke like bodies seen at NOA and Pinheiro. |

|

Drill hole information |

· A summary of all information material to the under-standing of the exploration results including a tabulation of the following information for all Material drill holes: · easting and northing of the drill hole collar · elevation or RL (Reduced Level - elevation above sea level in metres) of the drill hole collar · dip and azimuth of the hole · down hole length and interception depth · hole length · If the exclusion of this information is justified on the basis that the information is not Material and this exclusion does not detract from the understanding of the report, the Competent Person should clearly explain why this is the case.

|

· A table containing all drill holes drilled and a list of significant assays from the results received is included with the release. · No material data has been excluded from the release. .

|

|

Data aggregation methods |

· In reporting Exploration Results, weighting averaging techniques, maximum and/or minimum grade truncations (e.g. cutting of high grades) and cut-off grades are usually Material and should be stated. · Where aggregate intercepts incorporate short lengths of high-grade results and longer lengths of low grade results, the procedure used for such aggregation should be stated and some typical examples of such aggregations should be shown in detail. · The assumptions used for any reporting of metal equivalent values should be clearly stated. |

· Length weighted average grades have been reported. · No high-grade cuts have been applied to reported grades. · Metal equivalent values are not being reported; however, Li is reported as ppm and converted to the oxide Li2O for resource purposes. The conversion factor used is to divide the Li value by 10,000 and multiplying by 2.153 to represent the value as a percentage. |

|

Relationship between mineralisation widths and intercept lengths |

· These relationships are particularly important in the reporting of Exploration Results. · If the geometry of the mineralisation with respect to the drill hole angle is known, its nature should be reported. · If it is not known and only the down hole lengths are reported, there should be a clear statement to this effect (e.g. 'down hole length, true width not known'). |

· The majority of holes have been drilled at angles to intersect the mineralisation in perpendicular relation to the pegmatite |

|

Diagrams |

· Appropriate maps and sections (with scales) and tabulations of intercepts should be included for any significant discovery being reported. These should include, but not be limited to a plan view of drill hole collar locations and appropriate sectional views. |

· A relevant plan showing the drilling is included within this release.

|

|

Balanced Reporting |

· Accuracy and quality of surveys used to locate drill holes (collar and down-hole surveys), trenches, mine workings and other locations used in Mineral Resource estimation. · Where comprehensive reporting of all Exploration Results is not practicable, representative reporting of both low and high grades and/or widths should be practiced to avoid misleading reporting of Exploration Results. |

· All relevant results available have been previously reported. |

|

Other substantive exploration data |

· Other exploration data, if meaningful and material, should be reported including (but not limited to): geological observations; geophysical survey results; geochemical survey results; bulk samples - size and method of treatment; metallurgical test results; bulk density, groundwater, geotechnical and rock characteristics; potential deleterious or contaminating substances. |

· Geological mapping and rock chip sampling has been conducted over the project area. |

|

Further work |

· The nature and scale of planned further work (e.g. tests for lateral extensions or depth extensions or large- scale step-out drilling). · Diagrams clearly highlighting the areas of possible extensions, including the main geological interpretations and future drilling areas, provided this information is not commercially sensitive. |

· The present drill programme has been designed to infill previous drilling to attain a measured or indicated class for an upcoming resource estimation. Further work is being planned as part of a second phase of resource infill drilling. · Economic evaluation of the defined Mineral Resources, will be completed after the second phase of drilling. |

[1]Cautionary Statement: The potential quantity and grade of the Additional Exploration Targets is conceptual in nature, there has been insufficient prospecting work to estimate a mineral resource and it is uncertain if further prospecting will result in defining a mineral resource.

RNS may use your IP address to confirm compliance with the terms and conditions, to analyse how you engage with the information contained in this communication, and to share such analysis on an anonymised basis with others as part of our commercial services. For further information about how RNS and the London Stock Exchange use the personal data you provide us, please see our Privacy Policy.